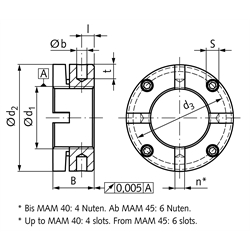

Precision locknut MAM 35 with axial clamping M35 x 1.5

| Typ | MAM 35 |

|---|---|

| d1 [mm] | M35 x 1,5 |

| d2 [mm] | 65 |

| d3 [mm] | 58 |

| B [mm] | 22 |

| b H11 [mm] | 6 |

| tmin. [mm] | 8 |

| l [mm] | 6 |

| n [mm] | 6 |

| S [mm] | M6 |

| TAS1) [Nm] | 5 |

| FB2) [k N] | 330 |

| TL3) [Nm] | 100 |

| TA14) [Nm] | 40 |

| J5) [kgcm2] | 2,4 |

| Gewicht [g] | 326 |

Material: Tempered steel 42CrMo4, black oxided.

Reusable shaft nut with integrated locking devices. By fastening the locking screws, the clamping segments are elastically deformed and pressed against the shaft thread to secure the nut. For applications with high axial load, which require a high stiffness, high precision and trustable locking.

1) Fastening torque of locking screw. The screws must be tightened evenly and crosswise in several steps.

2) Breaking load in axial direction. Depending on the application, a security factor has to be choosen.

3) Breakaway torque of the nut, with screws tightened with torque TAS and nut fastened with torque TA1.

4) Fastening torque of the nut, as a reference, to provide the specification of the breakaway torque. If the nut is fastened by using a special wrench fitting in all slots from the face side, the maximum fastening torque is 2 x TA1.

5) Mass moment of intertia.